Welding is a very rewarding career. It involves working with metal to fabricate or create something that can then be used for a specific purpose. It uses extreme heat to break down the chemical bonds in metal so that they re-fuse together. There are many different welding methods, including spot welding, metal inert gas (MIG), and tungsten inert gas. These use different forms of welding, including arc welding, gas welding, and more.

Missouri Welding Institute is a welding school in Nevada, Missouri, that offers top-notch welding programs that will launch your career as a welder. Our welding programs include Master Pipe Welding and Fitting, Master Structural Welding and Fitting, and custom welding programs you can create. Below, we’ll review some common welding terms you should know. Contact our welding trade school for enrollment information today!

Common Welding Terms You Should Know

Alloy

An alloy is a conglomeration of metals, which is usually added to either make it stronger or to give the metal added properties for particular uses. For instance, chromium and nickel are often added to steel to make it more resistant to corrosion and rust.

Arc Welding

Arc welding is a type of welding that is very common and one that we teach here at Missouri Welding Institute in Nevada. It gets its name from the fact that it uses an arc (which is a type of fusion process that uses an electrical power source and an electrode to fuse metal together) that creates the heat.

Base Metal

Depending on its uses, a base metal can refer to two things in welding. It can be the metal that has just been cut, or it can be referring to the majority of the metal that you are working with.

Carbon-Arc Welding

A specific type of welding that still uses an arc, but this type of welding creates an arc between the carbon electrode and a metal.

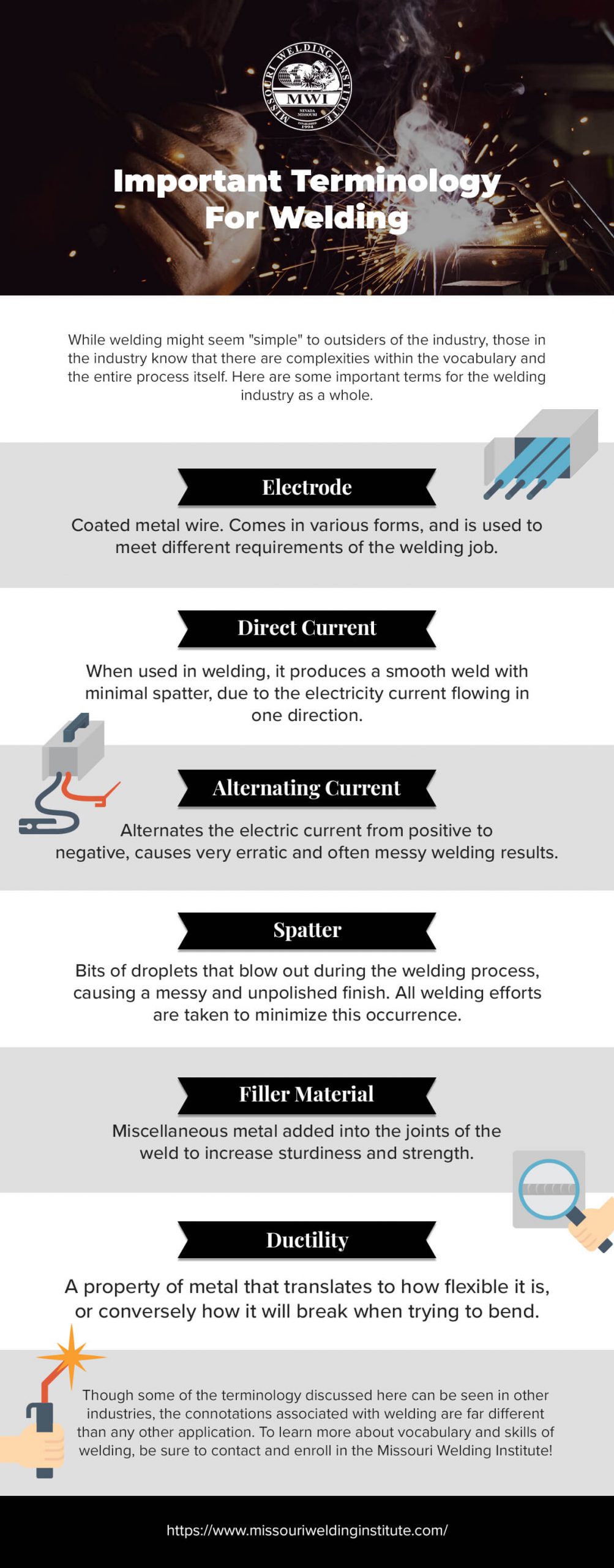

Electrode

At its base, an electrode is a coated metal wire. It is usually made out of similar metals that you are welding. There are different kinds of electrodes, each having different properties that are used to meet the different requirements of the welding job. For instance, some of the characteristics welding materials need include: strength, corrosion resistance, ductility, and the like.

Two common types of electrodes include the covered electrode and the coated electrode. A covered electrode is a metal base that is covered with different kinds of materials, such as flux or paper, to create a stable arc. This allows for a better weld all-around. A coated electrode is your base metal that is covered in a substance, such as paint, that will produce a gas that shields the arc from contaminants in the atmosphere. The problem with contaminants is that they can produce porosity and longitudinal cracking. Thus, coated electrodes create a smooth and sound weld that is truly magnificent to behold.

Direct Current

Most of us have heard of direct currents as it pertains to electricity. However, they are also important in welding. When a direct current is employed in welding, you get a very smooth weld with little spatter because the flow of a direct current is in one direction (from negative to positive). You can weld in the negative pole of the arc (known as direct current electrode negative), or you can weld in the positive pole of the arc (known as direct current electrode positive).

Alternating Current

As you know from electricity, alternating current travels in both directions, changing periodically from positive to negative. Direct current is preferred in welding because due to the constant change in the direction, your weld can be very erratic, and thus not clean.

Spatter

Like the name implies, spatter is the bits of droplets that blow out when you are welding, which most of you have seen in pictures of welding. No welder likes spatter, and it’s best to avoid it at all costs. Spatter flies out and sticks itself to everything, leaving nasty messes behind and potentially ruining your welding project. The quality of the weld, the coating of the weld, and the filler of the weld all a part in the amount of spatter that is produced.

Filler Material

Filler in welding is the metal you add while you are welding. Filler is mostly used in joints.

Ductility

A property of metal that will tell you how flexible it is, or how susceptible it is to being bent or breaking. This is important to keep in mind during your welding projects because some welding projects you want to be strong, and some you definitely want to be flexible, depending on the application.

Choose Missouri Welding Institute as your welding school of choice

Welding is a rewarding and dynamic career that you should consider. Creating works of art out of nothing is something most welders take pride in. Every day you are welding is different, and each welding project you work on will be a learning experience. Our campus is sprawling, containing a shop area, pipe fitting laboratory, classrooms, library, and offices. Some of our welding training equipment includes hand-operated cutting tools, plasma cutting torches, high-frequency arc welders, articulated clean air retrieval arms, grinding stations, pipe beveling machines, and so much more. Our welding staff has decades of experience in all industries where welding is used, such as construction and manufacturing. They bring their knowledge and experience to the classroom everyday so you can learn.

Missouri Welding Institute has partnered with local apartment complexes in order to offer you superb housing arrangements that will meet your needs and that are close to our welding school. Choose from one-bedroom or two-bedroom options, and all utilities are included.

One of the big draws of our welding school is our job placement assistance and program after you’ve graduated with a welding certificate. We hold regular job fairs here at our school, and we have a wide alumni network to draw upon as well. In addition, we have great ties with our surrounding communities and local businesses who actively seek to employ our graduates if you are looking to stay in the area. We provide help with resumes, job searches, and job interview skills. We’ve placed graduates all over the United States, as well as overseas in exciting, rewarding, and fulfilling job opportunities.

Our Master Pipe Welding and Fitting Course as well as our Master Structural Welding and Fitting Course will teach you everything you need to know for your welding career. If you are thinking about a career in welding, we invite you to visit our welding school in Nevada, Missouri, today!