Welding is a fundamental skill in various industries like construction, oil and gas, and power generation. Among the many welding techniques, pipe welding is one of the most specialized and essential. Pipe welding requires welders to master specific welding positions that determine how the pipe is oriented and how the welder must manipulate the weld pool.

Understanding Welding Positions

Before diving into the specific pipe welding positions, it’s crucial to understand what welding positions are and why they matter. A welding position refers to the orientation of the pipe or workpiece and the type of weld joint being created. Each position presents unique challenges due to gravity, accessibility, and the welder’s ability to control the weld pool.

The most common positions in pipe welding are:

- Flat Position (1G, 1F)

- Horizontal Position (2G, 2F)

- Vertical Position (3G, 3F)

- Overhead Position (4G, 4F)

- Inclined Pipe Position (5G, 6G, and 6GR)

Each position may apply to either a groove weld (G) or a fillet weld (F). The most commonly used pipe welding positions are 1G, 2G, 5G, and 6G, which are essential for both fieldwork and shop work.

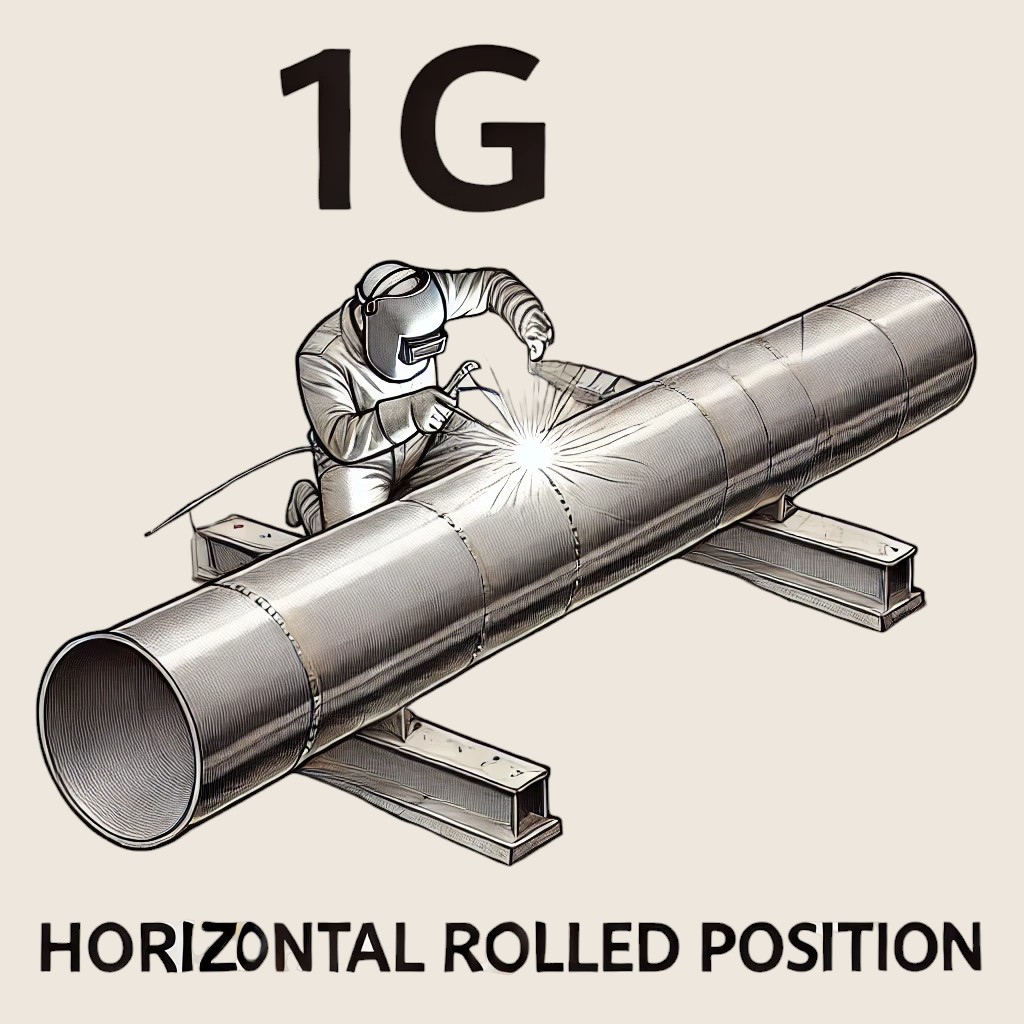

Flat Welding Position (1G)

The 1G welding position, also known as the flat position, is the easiest and most basic pipe welding position. In this position, the pipe is placed horizontally, and the welder performs the weld from above while rotating the pipe along the X-axis. Gravity works to the welder’s advantage, holding the molten weld pool in place.

Characteristics of 1G Welding

- Rotating Pipe: The welder remains stationary while the pipe rotates, ensuring a uniform weld.

- Easy Manipulation: The position allows for good visibility of the weld pool and easier manipulation of the torch or electrode.

- Suitable for Beginners: This position is commonly used for beginners to develop their welding skills and is ideal for groove welds (1G) and fillet welds (1F).

Applications of 1G Welding

1G welding is often used in workshops or fabrication settings where pipes can be easily rotated. This position is typically employed for welding smaller pipes or spools before they are installed in their final location.

Challenges of 1G Welding

While 1G is the easiest position, it still requires the welder to maintain even penetration throughout the joint. Heat control is essential to avoid overheating, warping, or weakening the joint.

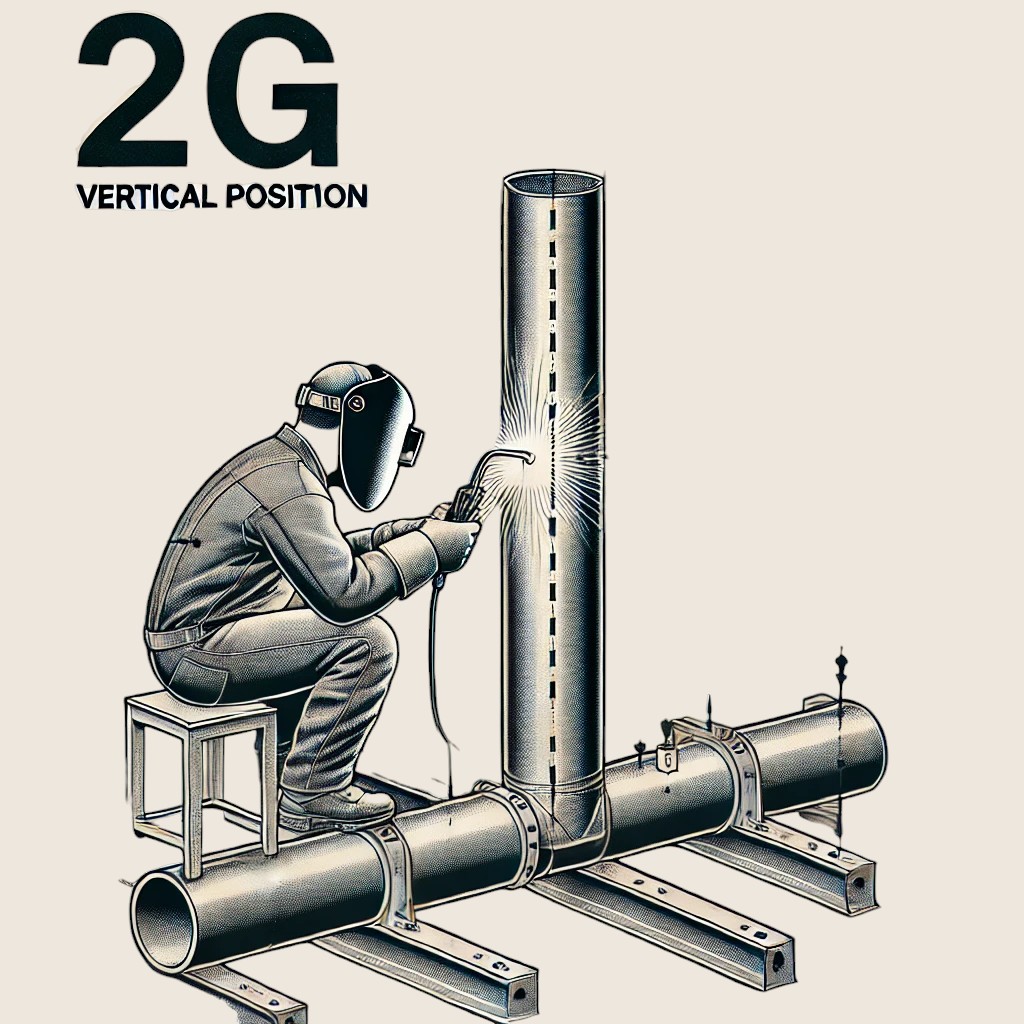

Horizontal Welding Position (2G)

The 2G welding position involves welding a vertical pipe horizontally around the pipe’s circumference. In this position, the welder moves horizontally, while the pipe remains stationary.

Characteristics of 2G Welding

- Stationary Pipe: Unlike in the 1G position, the pipe is fixed, and the welder must move around the pipe.

- Horizontal Welding: Gravity now acts sideways on the weld pool, making it more difficult to control the molten metal.

- Groove and Fillet Welds: This position is used for both groove welds (2G) and fillet welds (2F). The groove weld is more challenging, as there is no support for the weld pool, unlike in the 2F fillet weld.

Applications of 2G Welding

2G welding is commonly used in industrial and structural applications, such as oil and gas pipelines, where pipes are often installed vertically. It is also employed in fieldwork, where rotating the pipe is impractical or impossible.

Challenges of 2G Welding

The primary challenge in 2G welding is controlling the weld pool, as gravity pulls the molten metal away from the joint. Proper heat control, electrode angle, and technique are necessary to prevent underfill or lack of fusion, which can compromise the weld quality.

Vertical Welding Position (3G)

In the 3G welding position, the weld is performed on a vertically oriented joint. The welder must work either from the bottom up (vertical up) or from the top down (vertical down).

Characteristics of 3G Welding

- Vertical Up vs. Vertical Down: In vertical up welding, the welder moves upward, which is ideal for thicker materials. In vertical down welding, the welder moves downward, which is faster but may result in weaker welds.

- Weaving Technique: A zigzag or triangular weaving technique is often used to ensure even heat distribution and prevent sagging of the weld pool.

- Gravity’s Impact: Gravity plays a significant role in this position, making the molten weld pool more difficult to control.

Applications of 3G Welding

The 3G position is frequently used in structural welding, such as building vertical beams or columns. It’s also commonly used in vertical pipe welding applications where welders need to create vertical seams.

Challenges of 3G Welding

The main challenge is preventing the molten weld pool from sagging or dripping due to gravity. Adjusting the heat, travel speed, and angle is crucial to achieving a high-quality weld. Vertical up welding provides better penetration but requires more control, while vertical down is faster but risks weak joints.

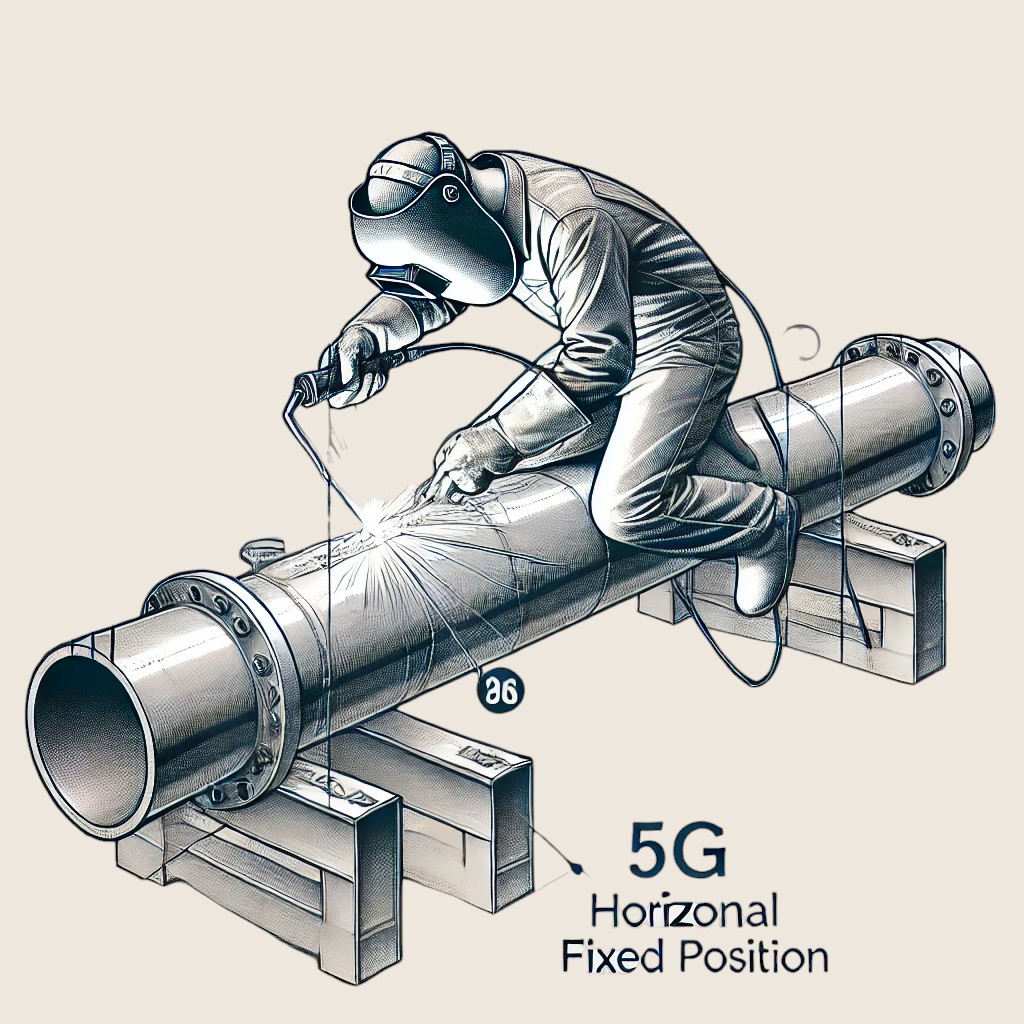

Horizontal Fixed Welding Position (5G)

The 5G position is used specifically for pipe welding. In this position, the pipe is placed horizontally but remains fixed in place, so the welder must move around the pipe to complete the weld.

Characteristics of 5G Welding

- Fixed Pipe: The pipe is stationary, and the welder moves around it.

- Multiple Positions: The welder transitions through different positions (flat, horizontal, vertical, and overhead) as they move around the pipe.

- Used for Groove Welds: This position is primarily used for groove welds in pipe welding applications.

Applications of 5G Welding

The 5G position is commonly used in field installations where rotating the pipe is not feasible. It’s frequently employed in industries such as oil and gas, petrochemical plants, and power generation, where large pipelines are welded in place.

Challenges of 5G Welding

The biggest challenge in 5G welding is controlling the weld pool as the welder moves between different positions. Gravity can affect the molten metal differently in each position, requiring the welder to constantly adjust their technique to ensure even penetration and avoid defects such as sagging or undercutting.

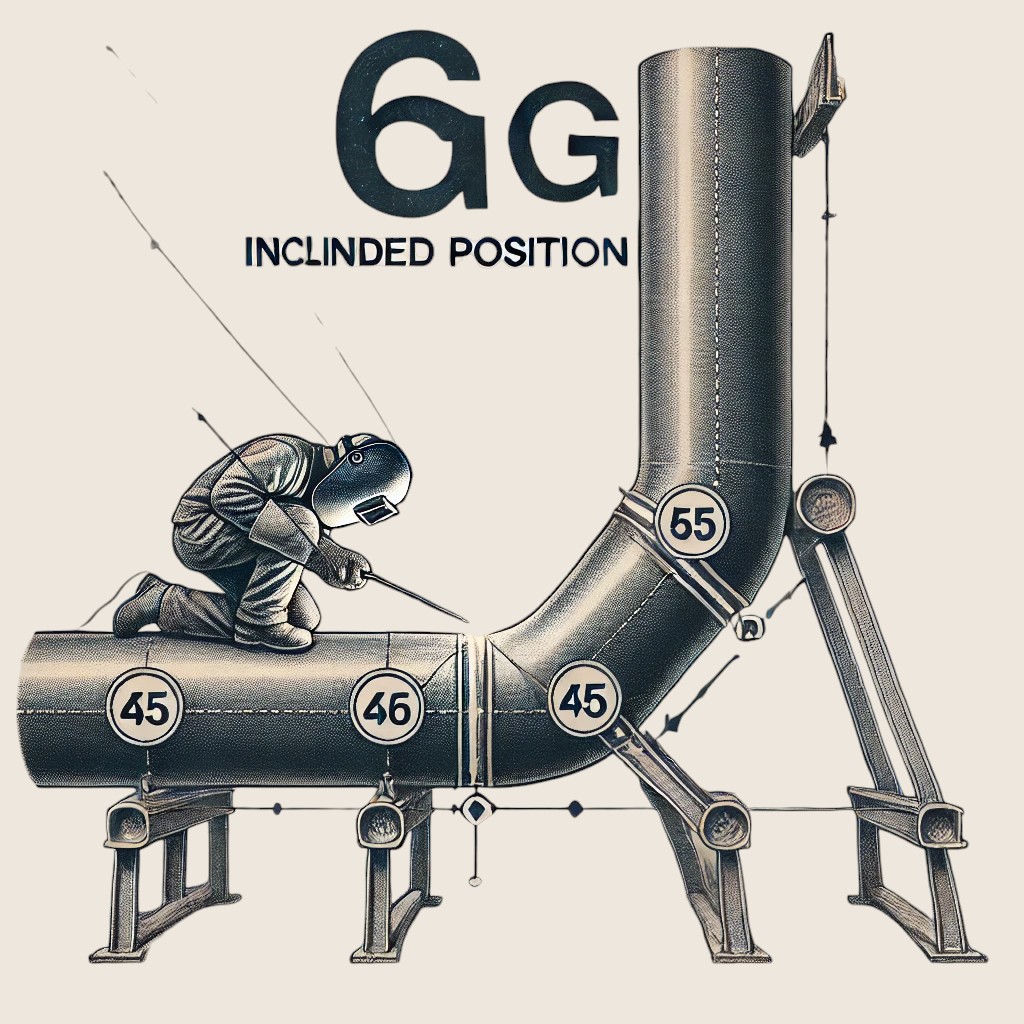

Inclined Welding Position (6G)

The 6G welding position is one of the most advanced and difficult positions to master. The pipe is fixed at a 45-degree angle, and the welder must perform the weld by moving around the pipe.

Characteristics of 6G Welding

- Inclined Pipe: The pipe is positioned at a 45-degree angle, adding complexity to the weld.

- Multiple Welding Positions: The welder must use a combination of flat, horizontal, vertical, and overhead welding techniques to complete the weld.

- Certification Requirement: The 6G position is often used in certification tests because of its difficulty. Welders certified in 6G are considered capable of welding in any other position.

Applications of 6G Welding

6G welding is used in high-pressure pipelines, industrial plants, and construction projects where the highest level of skill is required. It is a standard for pipe welding in the oil and gas industry.

Challenges of 6G Welding

The 6G position is challenging because the welder must navigate through different positions, with gravity affecting the weld pool differently at each angle. Mastery of heat control, travel speed, and technique is critical to avoid defects. Due to its complexity, 6G certification is one of the most sought-after qualifications in the welding industry.

Conclusion

Mastering the various pipe welding positions—1G, 2G, 5G, and 6G—is essential for any professional welder working in industrial and construction settings. Each position brings its own challenges related to gravity, accessibility, and the welder’s ability to control the weld pool.

While 1G is suitable for beginners, the 6G position demands a high level of expertise and experience. Understanding and mastering these positions not only opens the door to specialized jobs but also sets the foundation for success in a demanding and rewarding industry.

Welders who are certified in 6G are highly sought after and can work in any position, making these certifications the gold standard in the field.