Pipe welding is a specialized and demanding field within the welding profession. It requires not only technical skill but also the ability to work in challenging conditions and maintain a high level of precision. For those considering a career in welding, it’s natural to wonder: Is pipe welding hard? In this article, we’ll explore the challenges of pipe welding, the skills needed to succeed, and why, despite its difficulties, pipe welding can be a rewarding and lucrative career.

What is Pipe Welding?

Definition and Importance

Pipe welding is a specialized branch of welding that focuses on joining sections of pipes used in various industries, such as oil, gas, water, and chemical processing. These pipes are often used to transport vital resources over long distances, making the integrity of the welds critical to ensuring that the materials being transported remain contained and safe.

Role in Infrastructure

Pipe welding plays a crucial role in constructing and maintaining essential infrastructure. Whether it’s oil and gas pipelines stretching across vast distances, water pipelines delivering clean water, or chemical pipelines carrying industrial substances, high-quality welding ensures the longevity and efficiency of these systems. Without skilled pipe welders, the risk of leaks, failures, and environmental hazards increases significantly.

Types of Pipelines Commonly Welded

- Oil and Gas Pipelines: Require high safety standards to prevent leaks and ensure efficient transportation.

- Water Pipelines: Essential for delivering clean water; welding must ensure no contamination occurs.

- Chemical Pipelines: Require careful welding to prevent hazardous leaks, making this a highly specialized area.

Why is Pipe Welding Considered Challenging?

Technical Skills Required

Pipe welding demands a high level of technical skill. Unlike welding on flat surfaces, pipe welding involves working with curved surfaces that require multiple positions and angles. Welders must be proficient in various welding processes, such as Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW or TIG), and Gas Metal Arc Welding (GMAW or MIG). Each of these techniques presents its own set of challenges.

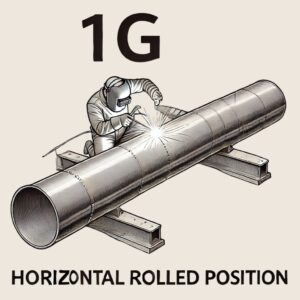

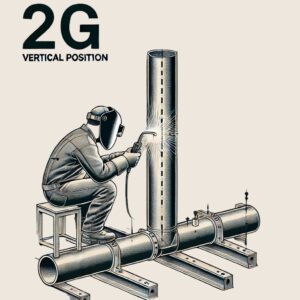

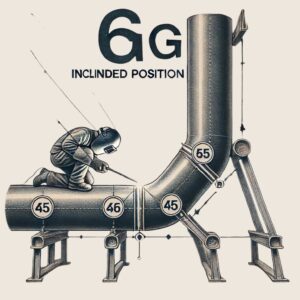

Maintaining the correct travel angle is crucial in pipe welding. The angle, which changes with the diameter of the pipe, must be consistent to avoid defects like spatter and poor penetration. Additionally, mastering different pipe welding positions, from 1G (basic) to 6G (complex), requires significant practice and precision.

Challenging Welding Positions

One of the primary reasons pipe welding is considered difficult is the variety of welding positions required. Each position presents unique challenges:

- 1G Position: The pipe is horizontal, and welding is performed from the top. This is the easiest position but still requires skill for even penetration.

- 2G Position: The pipe is vertical, and welding is performed horizontally around the pipe. Maintaining a consistent angle is crucial.

- 5G Position: The pipe is horizontal but cannot be rotated. The welder must move vertically, adding complexity.

- 6G Position: The pipe is angled at 45 degrees and fixed in place. The welder must move around the pipe, making this the most challenging position.

Tough Working Conditions

Pipe welders often work in challenging environments. Pipelines are frequently located in remote areas, exposed to the elements, or in confined spaces that are difficult to access. Welders may find themselves working in extreme heat or cold, dealing with high winds, or working in uncomfortable positions for extended periods.

These tough conditions add to the difficulty of the job. For example, in cold weather, the metal can become brittle, making it more challenging to achieve a good weld. In hot weather, the welder must deal with the discomfort of wearing heavy protective gear while maintaining focus and precision. The physical demands of the job, combined with the need to produce high-quality welds under these conditions, make pipe welding a challenging and demanding profession.

Precision and High Stakes

Pipe welding is a high-stakes job where precision is paramount. Any defect in the weld can lead to a failure in the pipeline, with potentially catastrophic consequences. Welders must follow strict procedures and often work under pressure to complete their tasks quickly and without errors.

Welds are often inspected using X-ray technology to ensure they meet the required standards. If a weld fails inspection, it must be repaired, which can be costly and time-consuming. In some cases, repeated failures can result in the welder losing their job. The pressure to perform at a high level consistently is a significant challenge in this field.

Overcoming the Challenges of Pipe Welding

Importance of Proper Training

Given the complexities and challenges of pipe welding, proper training is essential. A welder’s ability to perform well under pressure, adapt to different welding positions, and produce consistent, high-quality welds comes from rigorous training and practice.

Missouri Welding Institute offers one of the best Master Pipe Welding & Fitting courses in the nation. This program provides students with comprehensive training in all aspects of pipe welding, from basic techniques to advanced procedures. The curriculum is designed to equip students with the skills and knowledge needed to excel in the field, ensuring they are well-prepared for the challenges they will face on the job.

Gaining Experience

Experience is invaluable in pipe welding. While training provides the foundation, real-world experience is what hones a welder’s skills. Many welders start with simpler tasks and gradually take on more complex projects as they gain confidence and proficiency.

Working under the guidance of experienced welders, especially in a mentorship setting, can accelerate the learning process. Learning from those who have spent years in the field helps new welders understand the nuances of the job and pick up tips and techniques that can only be learned through experience.

Continuous Learning and Adaptation

The welding industry is constantly evolving, with new technologies, materials, and methods being introduced regularly. To stay competitive, welders must commit to continuous learning. This could involve taking additional courses, attending workshops, or staying updated on industry trends.

Missouri Welding Institute is dedicated to helping its students stay ahead of the curve. The institute regularly updates its curriculum to include the latest advancements in welding technology, ensuring that graduates are equipped with the most current skills and knowledge.

The Rewards of a Career in Pipe Welding

High Demand and Lucrative Pay

Pipeline welding is not only challenging but also highly rewarding. There is a strong demand for skilled pipe welders in the United States, particularly in industries like oil and gas, water utilities, and chemical processing. This demand is reflected in the compensation offered to welders.

The pay structure for pipeline welders is typically broken down into three components: arm pay (the hourly rate for welding), truck pay (a flat rate for using the welder’s truck and equipment), and per diem (a daily allowance for living expenses). On average, a pipeline welder can earn between $36 and $52 per hour for arm pay, with additional earnings from truck pay and per diem. With overtime and high-demand jobs, it’s not uncommon for welders to make over $100,000 annually.

Career Advancement Opportunities

Pipeline welding offers numerous opportunities for career advancement. With experience, welders can move into supervisory roles, become certified weld inspectors (CWI), or specialize in areas like underwater welding or working with exotic metals.

The transition from welder to CWI, for example, is a natural progression for those looking to extend their careers without the physical demands of welding. While the process of becoming a CWI is challenging, it opens up new opportunities and allows experienced welders to apply their knowledge in a new way.

Personal and Professional Fulfillment

Beyond the financial rewards, many welders find a deep sense of fulfillment in their work. Being part of large-scale infrastructure projects, contributing to the safety and efficiency of critical systems, and working as part of a team can be incredibly satisfying.

The bonds formed with fellow welders, especially on long projects, create a sense of camaraderie and community. For many, the lifestyle of a pipeline welder—despite its challenges—is a fulfilling and rewarding experience.

Why Choose Missouri Welding Institute?

Top-Quality Training Programs

Missouri Welding Institute is recognized as one of the leading institutions for welding education in the nation. Its Master Pipe Welding & Fitting course is designed to provide students with a deep understanding of pipe welding techniques, from the basics to advanced methods. The program combines classroom instruction with hands-on practice, ensuring that students are fully prepared for the demands of the job.

Industry Connections and Job Placement

One of the key advantages of training at Missouri Welding Institute is the strong industry connections the school has developed over the years. These connections often lead to job placement opportunities for graduates, making it easier for them to find employment in a competitive field. The institute’s reputation for producing highly skilled welders is well-known, and employers often seek out its graduates.

Supportive Learning Environment

At Missouri Welding Institute, the focus is not just on technical training but also on supporting students’ overall development. The school fosters a collaborative and supportive learning environment, where students are encouraged to ask questions, learn from one another, and build lasting relationships with their instructors and peers.

Conclusion

Pipe welding is undoubtedly a challenging profession, requiring a high level of skill, precision, and resilience. However, for those willing to put in the effort, it offers significant rewards—both financially and personally. With the right training and support, such as that provided by Missouri Welding Institute, aspiring welders can overcome the challenges and build successful careers in this vital field. If you’re considering a career in welding, pipeline welding is an opportunity worth pursuing, especially with the comprehensive training available at Missouri Welding Institute.

The role of pipe welders in maintaining and developing the infrastructure that keeps our world running is indispensable, and the skills you gain in this field will serve you well throughout your career.